menuproductsPRODUCT DISPLAY

- SMC brand

- Air Management System

- Directional Control Valves

- Air Cylinders

- Rotary Actuators/Air Grippers

- Electric Actuators/Cylinders

- Vacuum Equipment (VacuumGenerators/Vacuum SuctionCups/0ther)

- Air Preparation Equipment

- Modular F.R.L./Pressure ControlEquipment

- Fittings and Tubing

- Flow Control Equipment

- Sensors/Switches

- Process Valves

- Temperature Control Equipment

- Static Neutralization Equipment

- Silencers/Exhaust Cleaners/BlowGuns/Pressure Gauges

- SHELE brand

- Linear motor

- Rotor Stator

- Driver

- DD motor

- KK module

- Electric grippering

- GTH series embedded slide

- P series standard slide

- EGT series timing belt slide

- MK series timing belt slide

- EG series guide rod electric cylinder

- YH series high-precision electric cylinder

- C series compact electric cylinder

- ES series standard electric cylinder

- A-series heavy-duty electric cylinder

- Slot type photoelectric/safety grating

- Precision reducer

- Hollow rotating platform

- Steering gear

- Precision displacement platform

Your location:Home >>Products >>SMC brand >>Electric Actuators/Cylinders >>Grippers for CollaborativeRobots

Product Introduction

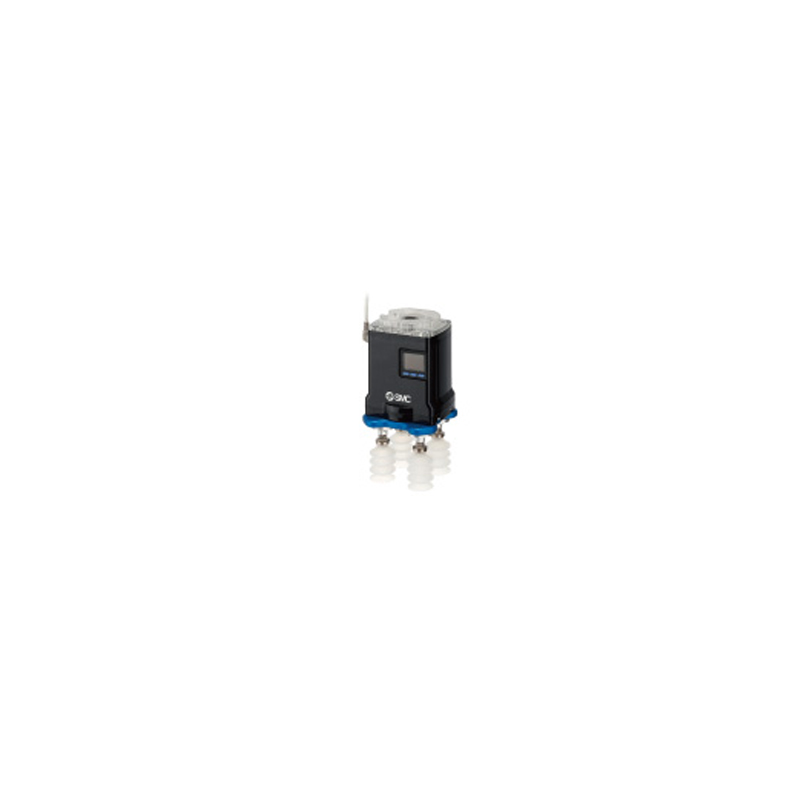

- ·Vacuum gripper without gas source

·Simply connect the electrical wiring connectors to operate

Built in vacuum pump, can be used in places without air source

·Uniting the peripheral components required for adsorption

Integrated with vacuum pump, atmospheric opening valve, pressure display, and suction cup

·Reduce current consumption by up to 64%

Automatic/manual mode, achieving energy-saving operation

·Lightweight: 556g

·Rich suction cup expansion products corresponding to various workpiece shapes

·Installation specifications: Complies with ISO9409-1-50-4-M6

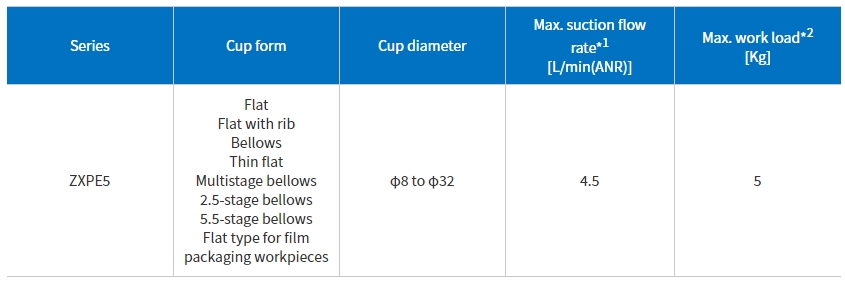

The maximum suction flow rate * 1 is determined based on the operating mode of the gripper determined by our company's measurement conditions: the value in continuous mode (continuous operation state of the vacuum pump). May vary due to atmospheric pressure (weather, altitude, etc.) and measurement methods.

The maximum transportable weight * 2 is limited by the suction cup diameter, installation posture, and workpiece. Please use this product below the maximum transportable weight. If the maximum transportable weight is exceeded for adsorption and handling, it may cause the main body to malfunction and the workpiece to fall off.

Recommended News /news

Characteristics and main uses of electric cylinders

The basic three elements of an electric slide table

Maintenance of electric cylinder and electric slide table

Product proposal to reduce CO2 emissions

Energy saving and low-carbon actions help enterprises achieve sustainable development

Proposal for installing an air dryer

Tender Instructions for General Waste Recycling Business

menu

menu Language

Language

0577-6298 7777

0577-6298 7777